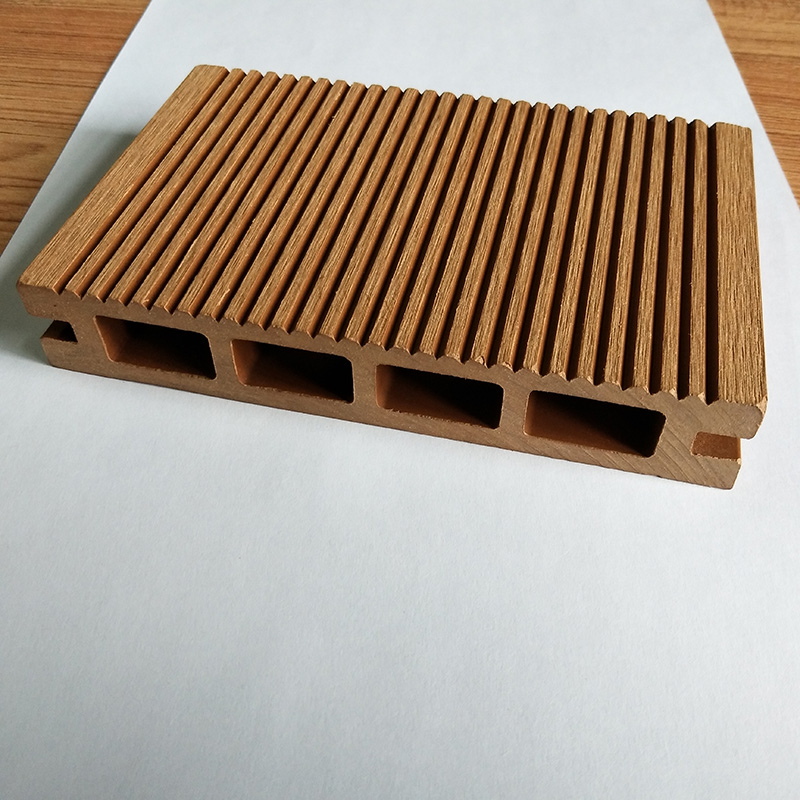

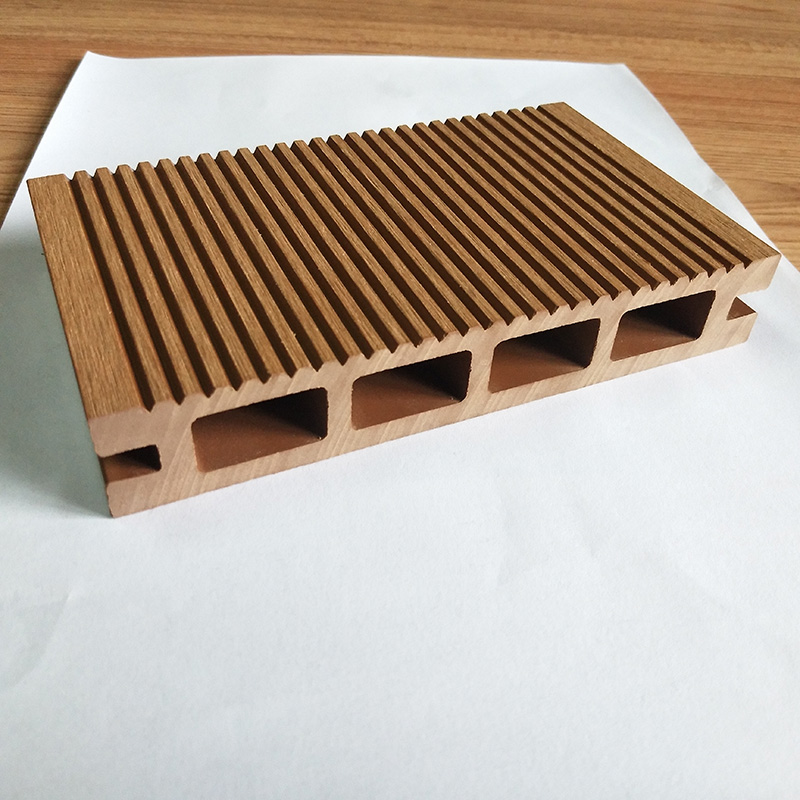

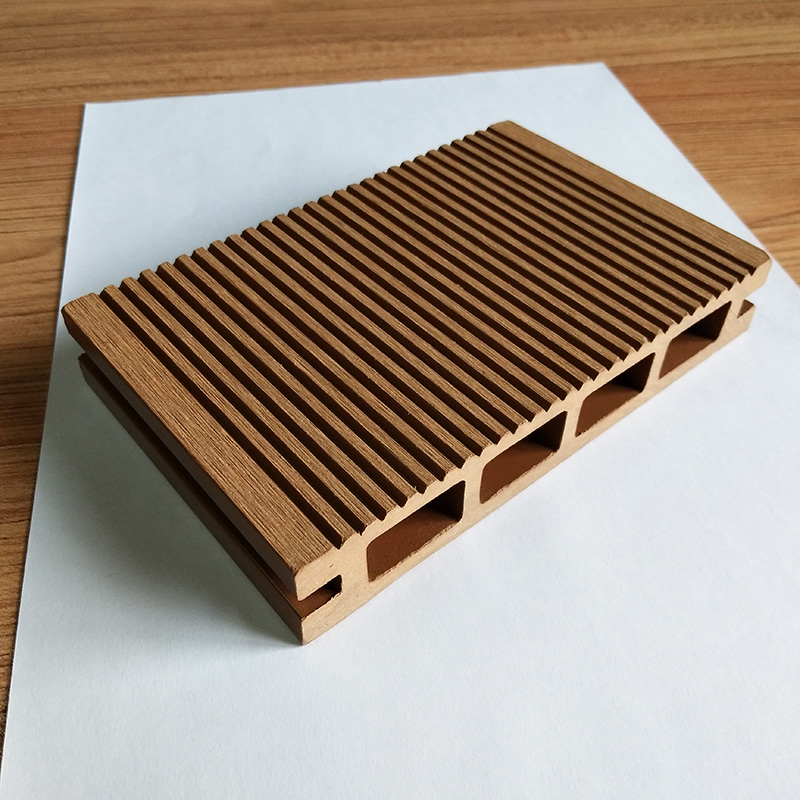

Floor Decking Square Hole APL 010

Model: 150*26

The installation is convenient, simple and labor-saving, and the later adjustment is as convenient as disassembly; It is not afraid of rain immersion and insect and ant bites. It has various colors, green environmental protection, no odor, no formaldehyde, light and climate resistance; It can be bonded and painted, easy to process and take care of. It can remove dust in rainy days, and the color is brand new.

Intruduction

Usually use Floor Decking Square Hole as a plate for manufacturing tree pools and flower boxes, as well as leisure integrated benches such as green spaces and squares. Even if the scene allows, it can be matched with other profiles to form simple and heavy fences, fences, etc.

Spceification

Basic Description | ||

Name | Wood-plastic floor | |

Serial Number | APL—140*25 | |

Material | Wood,HDPE,Some other Additive | |

Component: | 60% Wood+ 30% HDPE+ 10% Additives | |

Specification | 140*25(mm) | |

Color | Teak,Light Grey,Coffee,Chocolate,Black | |

Certificate | CE,SGS,ISO | |

Classification | Hollow and Solid | |

Application: | Outdoor, | |

Customized: | Non-Customized | |

MOQ: | 200 Sq m for WPC Decking | |

Main Market: | Southeast Asia,Central Asia,Europe & North America | |

Lead Time: | 15 Days for 1X20 GP Container | |

Transport Package: | Pallet ,Stretch Film,fluting paper (for whole container) | |

Advantages | Wear-resisting | Water-proof |

Dam-proof | Fireproof | |

No-pollution | Environmental Friendly | |

Project Display

Features

1. Eco-friendly made from recycled plastics and non-virgin wood.

2. Highly termite resistant.

3. Timber like finish for an excellent non-slip feel.

4. No staining or painting required.

5. Water and corrosion resistant, alkali-proof, moth-proof, stain-able and malleable, low pollution risk and odor-free.

6.Easy to install and clean.

7.Against UV.

Color matching / Accessory system

Surface Treatment

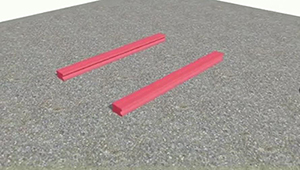

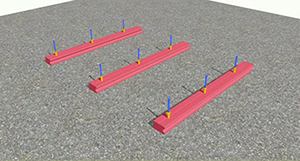

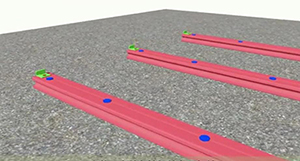

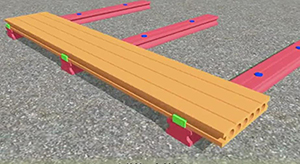

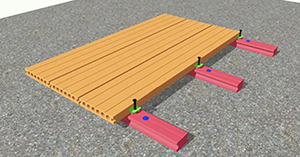

Installation steps

| 1. Lay keel on flat and hardened ground. |

2. The gap between two keels shall be controlled between 300mm and 350mm. |  |

| 3.The keel is fixed on the ground with 3 expansion screws per meter. |

4.Install special fasteners for fixing the first floor. |  |

| 5.Install the first floor. |

6.Install the second floor and secure with screws. |  |

| 7.Continue to install the remaining floors in this way. |

8.Install floor edging and secure with screws. |  |

Related News

Submitted successfully

We will contact you as soon as possible