Intruduction

Hollow WPC decking is made from recyclable wood flour, HDPE and other additives. Compared with the WPC solid decking, the hollow one is lighter and cheaper. Also it could present the different colors and the different style. The installation could be fast and easy. It’s complete name is Wood plastic composite decking(WPC Decking). And it performs with its excellent water resistance, especially suitable for use in a humid environment. It is commonly used for bathroom, parks, gardens,swimming pool and so on.

Spceification

Product Description | ||

Name | Wood-plastic floor | |

Material | Wood,HDPE,Some other Additive | |

Specification | 105*20,140*25,145*21 also could customized for clients | |

Color | Teak,Light Grey,Coffee,Chocolate,Black | |

Certificate | CE,SGS,ISO | |

Classification | Hollow and Solid | |

Advantages | Wear-resisting | Water-proof |

Dam-proof | Fireproof | |

No-pollution | Environmental Friendly | |

Features

1. Eco-friendly made from recycled plastics and non-virgin wood.

2. Highly termite resistant.

3. Timber like finish for an excellent non-slip feel.

4. No staining or painting required.

5. Water and corrosion resistant, alkali-proof, moth-proof, stain-able and malleable, low pollution risk and odor-free.

6.Easy to install and clean.

7.Against UV.

WPC Hollow Decking Floor

WPC Composite decking boards is made of 30% HDPE (Grade A recycled HDPE),60% Wood or Bamboo powder (Professionally treated dry bamboo or wood fiber), 10% Chemical Additives(Anti-UV agent, Antioxidant, Stabilizes, Colorants, Lubricant etc.)

WPC composite decking not only has real wood texture, but also has longer service life than real wood and requires little maintenance. So, WPC composite decking is a good alternative of other decking.

WPC (abbreviation: wood plastic composite)

Color matching / accessory system

Surface Treatment

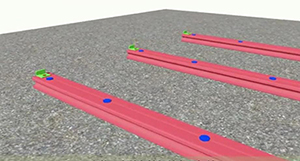

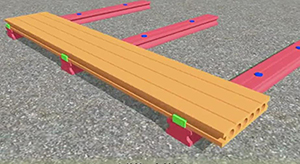

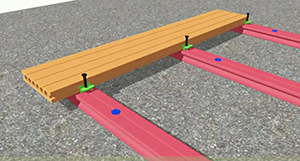

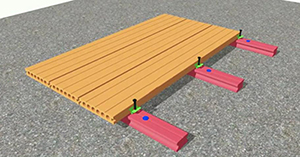

Installation steps

| 1. Lay keel on flat and hardened ground. |

2. The gap between two keels shall be controlled between 300mm and 350mm. |

|

| 3.The keel is fixed on the ground with 3 expansion screws per meter. |

4.Install special fasteners for fixing the first floor. |

|

| 5.Install the first floor. |

6.Install the second floor and secure with screws. |

|

| 7.Continue to install the remaining floors in this way. |

8.Install floor edging and secure with screws. |

|

Related News

Submitted successfully

We will contact you as soon as possible