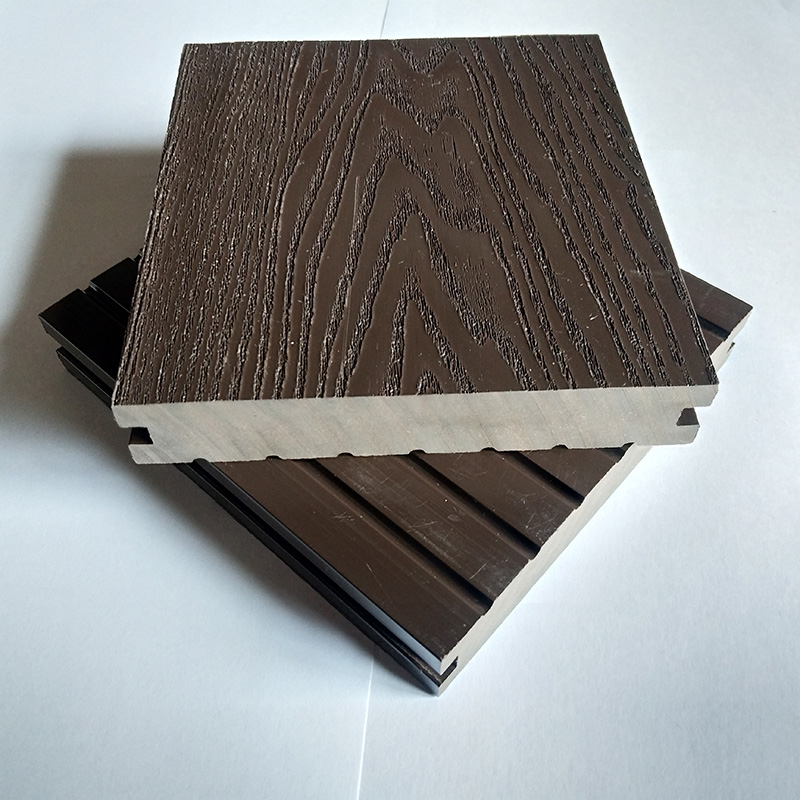

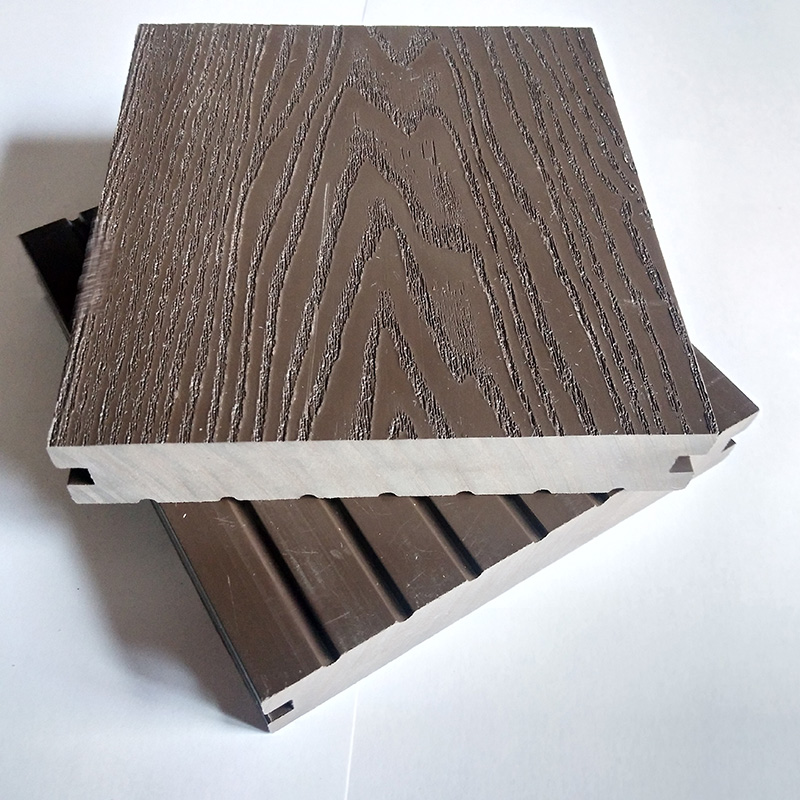

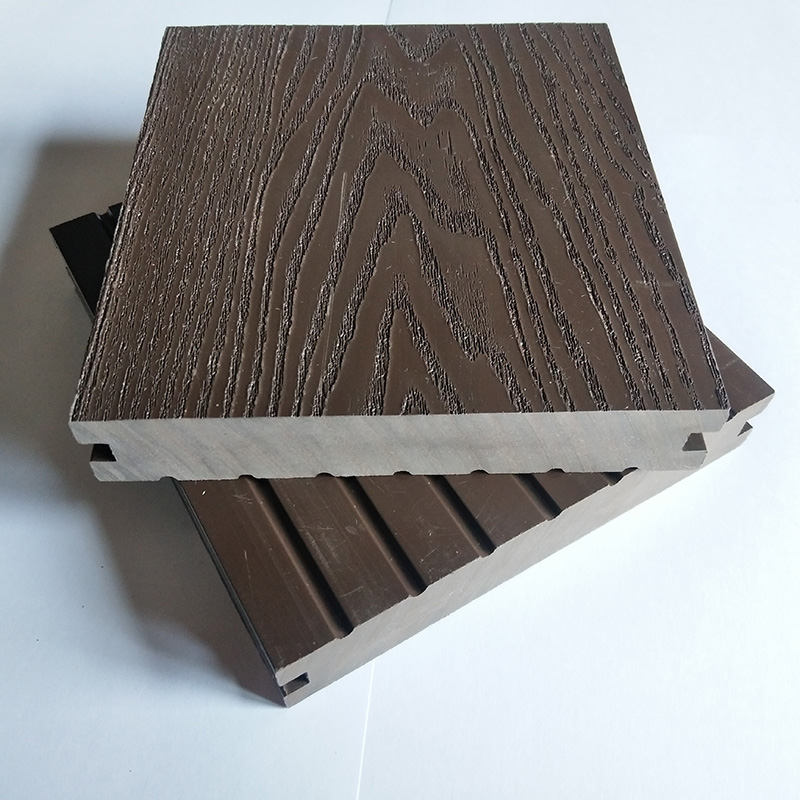

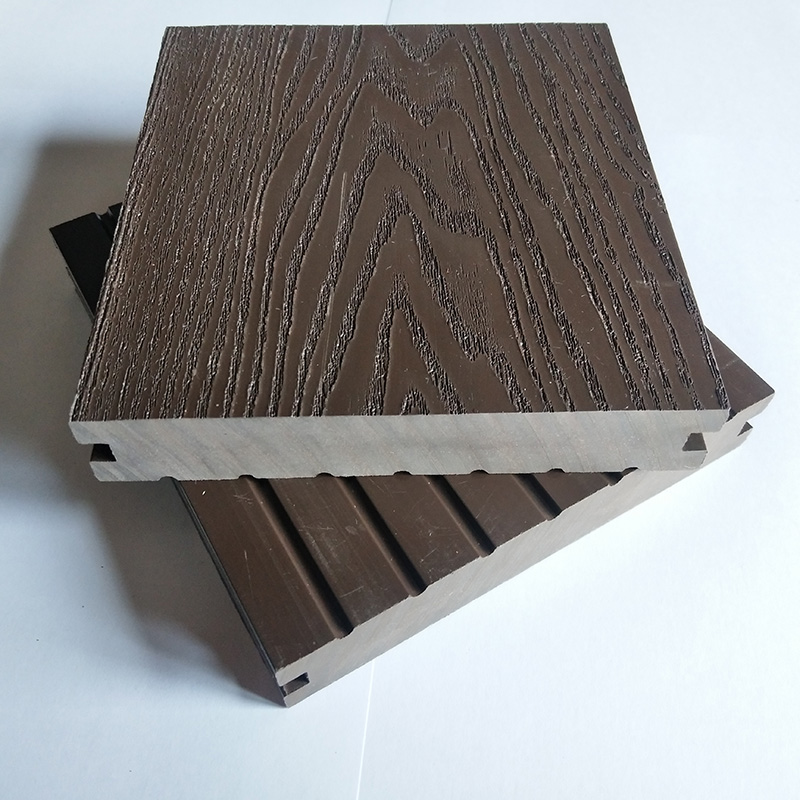

Embossed Solid Wood Board

Model: Embossed Solid Wood Board140 · 25

The installation is convenient, simple and labor-saving, and the later adjustment is as convenient as disassembly; It is not afraid of rain immersion and insect and ant bites. It has various colors, green environmental protection, no odor, no formaldehyde, light and climate resistance; It's easy to clean dust and paint after rain.

Intruduction

Stable floor decking is made from recyclable wood flour, hdpe and distinctive components. in comparison with the wpc strong decking, the hollow one is lighter and cheaper. also it could gift the particular colours and the specific fashion. the set up may be rapid and easy. it’s entire call is timber plastic composite decking(wpc decking). and it performs with its notable water resistance, specially suitable to be used in a moist surroundings. it's miles generally used for bathroom, parks, gardens,swimming pool and so on.

Spceification

Basic Description | ||

Name | Wood-plastic floor | |

Serial Number | APL—140*25 | |

Material | Wood,HDPE,Some other Additive | |

Component: | 60% Wood+ 30% HDPE+ 10% Additives | |

Specification | 140*25(mm) | |

Color | Teak,Light Grey,Coffee,Chocolate,Black | |

Certificate | CE,SGS,ISO | |

Classification | Hollow and Solid | |

Application: | Outdoor, | |

Customized: | Non-Customized | |

MOQ: | 200 Sq m for WPC Decking | |

Main Market: | Southeast Asia,Central Asia,Europe & North America | |

Lead Time: | 15 Days for 1X20 GP Container | |

Transport Package: | Pallet ,Stretch Film,fluting paper (for whole container) | |

Advantages | Wear-resisting | Water-proof |

Dam-proof | Fireproof | |

No-pollution | Environmental Friendly | |

Features

1. Eco-friendly made from recycled plastics and non-virgin wood.

2. Highly termite resistant.

3. Timber like finish for an excellent non-slip feel.

4. No staining or painting required.

5. Water and corrosion resistant, alkali-proof, moth-proof, stain-able and malleable, low pollution risk and odor-free.

6.Easy to install and clean.

7.Against UV.

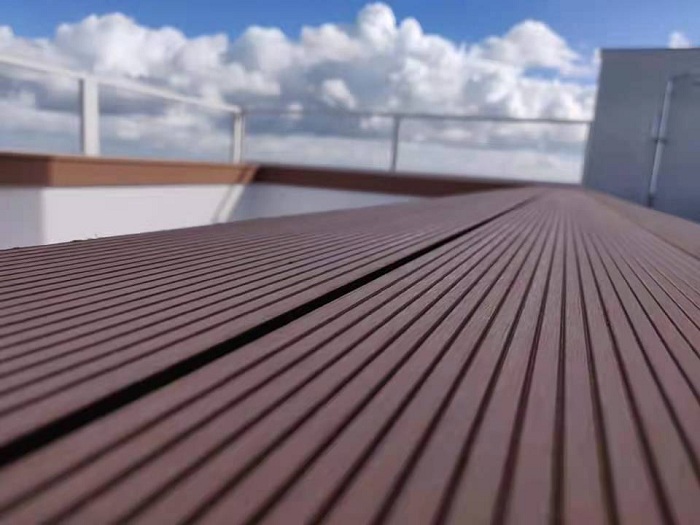

Project Dispaly

Purpose

The first use is plastic wood flooring, which is connected with the base surface with matching screws and buckles. The floor is arranged and spliced into a whole piece of wood plastic flooring in order. It is mostly used in engineering floors, outdoor squares and courtyard entertainment and leisure areas.

The second purpose is landscape wall and creative buildings. In terms of design compliance, appropriate location and reasonable matching, some buildings, such as landscape wall, terrace shading, roof swimming pool, etc.

The third purpose is to use it as a plate for manufacturing tree pools and flower boxes, as well as leisure integrated benches such as green spaces and squares. Even if the scene allows, it can be matched with other profiles to form simple and heavy fences, fences, etc.

The fourth use is for some indoor scenes. A layer of wood plastic floor can be protected in places prone to dust and water stains such as stairs, bathrooms and balconies.

Color matching / Accessory system

Surface Treatment

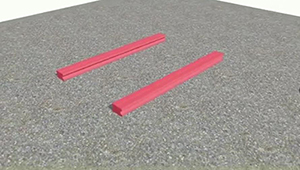

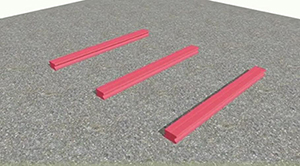

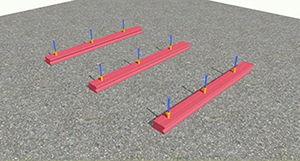

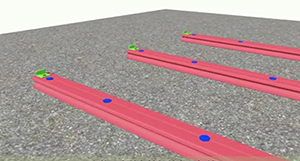

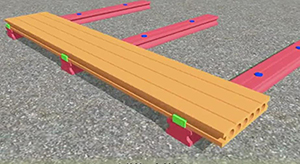

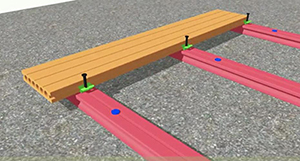

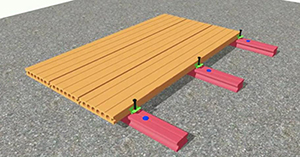

Installation steps

| 1. Lay keel on flat and hardened ground. |

2. The gap between two keels shall be controlled between 300mm and 350mm. |  |

| 3.The keel is fixed on the ground with 3 expansion screws per meter. |

4.Install special fasteners for fixing the first floor. |  |

| 5.Install the first floor. |

6.Install the second floor and secure with screws. |  |

| 7.Continue to install the remaining floors in this way. |

8.Install floor edging and secure with screws. |  |

Related News

Submitted successfully

We will contact you as soon as possible